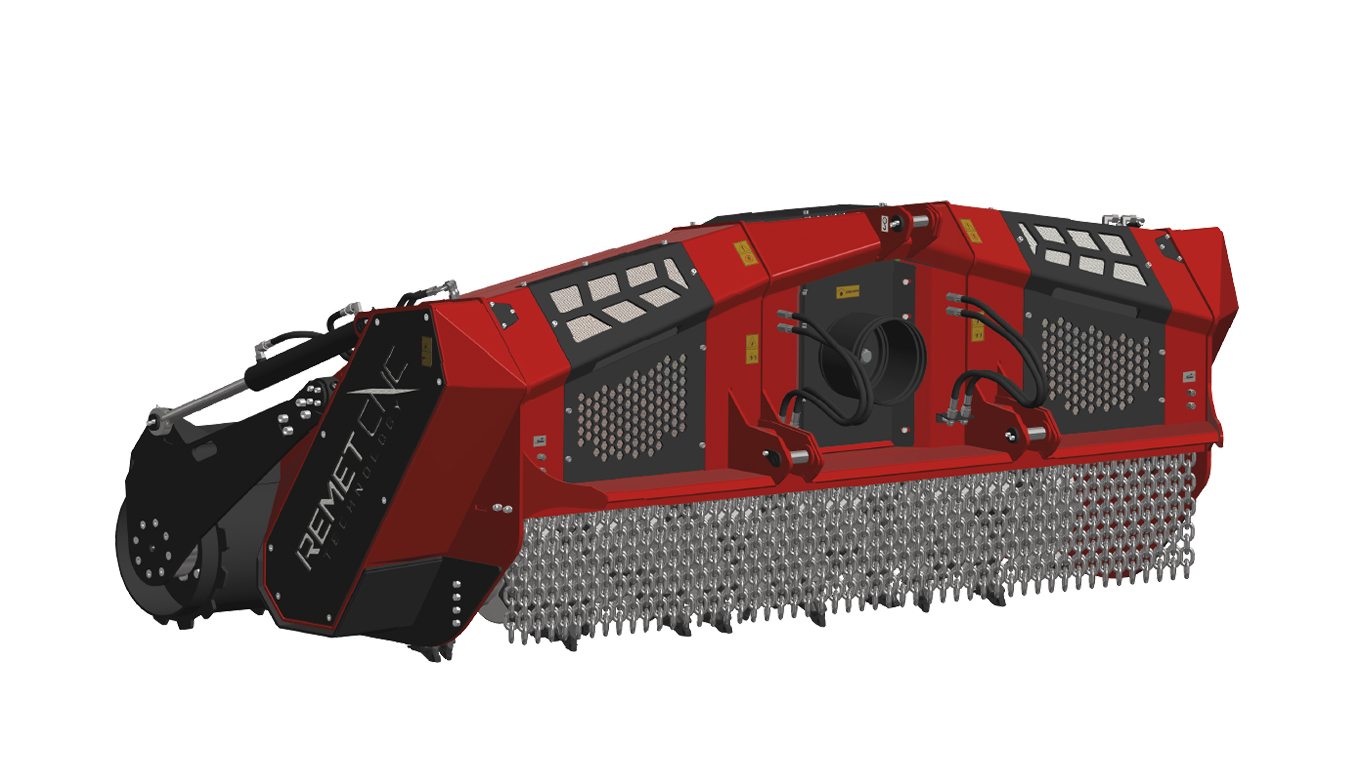

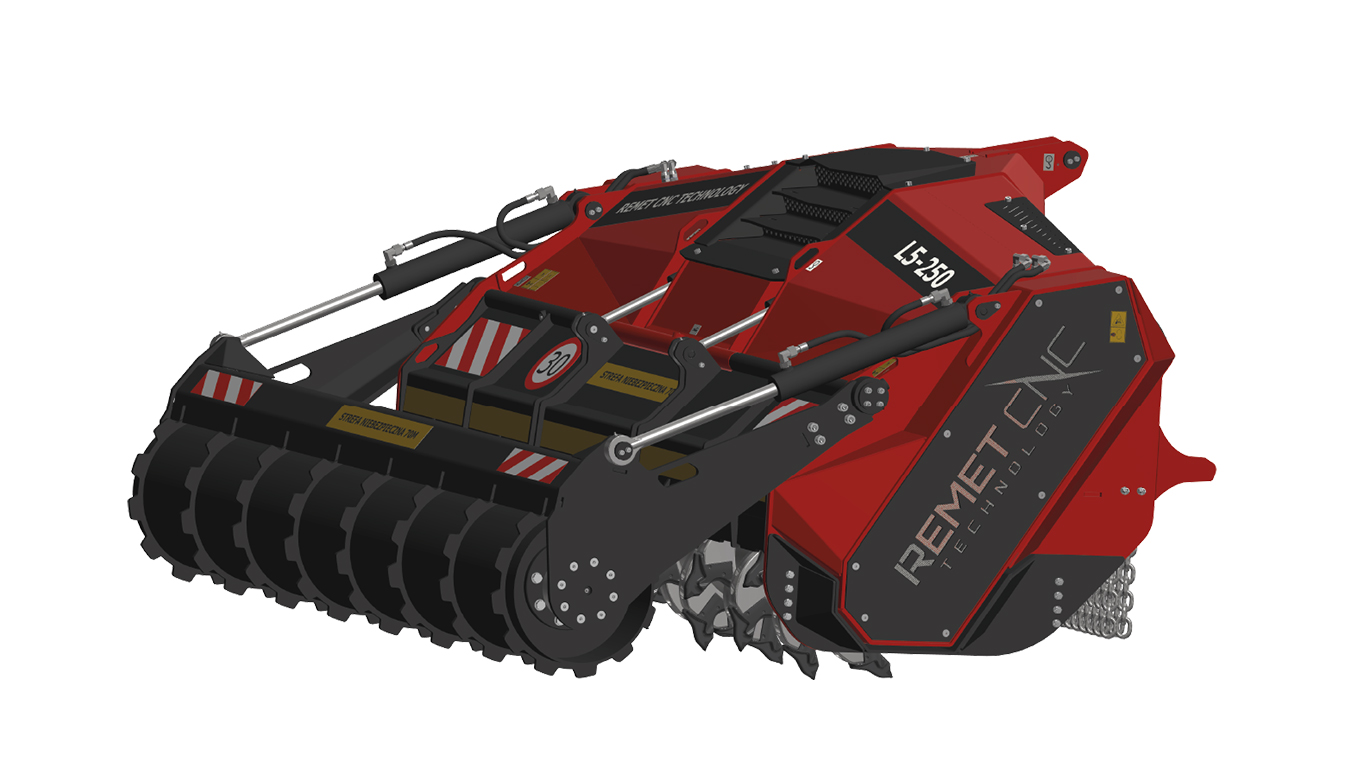

Forestry Tillers L5-250

| Min. / zalecana moc | 190-300 km |

|---|---|

| Szerokość robocza mulczera | 2500 mm |

| Maksymalna średnica rozdrabniania pni | 400 mm |

| Waga | 3490 kg |

| Typ pracy |

The machines from L5-250 group are the largest machines manufactured by REMET CNC, specially designed to work hard to meet the needs of professionals working with medium and high power tractors. This version of mulching machines is equipped with a special gearbox which provides ideal rotor rotation for perfect mulching and stump grinding in the

The machines from L5-250 group are the largest machines manufactured by REMET CNC, specially designed to work hard to meet the needs of professionals working with medium and high power tractors.

This version of mulching machines is equipped with a special gearbox which provides ideal rotor rotation for perfect mulching and stump grinding in the ground to a working depth of 50 cm. The machine recovers the soil preparing the ground for planting without any further treatment.

Model L5-250 with a working width of 2500 mm, the machine is designed to work with tractors with a minimum power of 190 hp at the revolutions of the power transmission shaft – 1000 rpm.

The machine has been designed for in-depth work, it can shred maximum tree trunks of 400 mm diameter.

Working mechanism with rotor diameter of 600 mm, equipped with a set of 78 forged exchangeable milling tools with increased durability thanks to the use of tungsten carbide plates with the possibility of quick disassembly by two-screw lock.

Power transition is done by a cross-gear gearbox, supplied by a renowned Italian manufacturer.

The dynamically balanced shaft/rotor, equipped with high quality Swedish spherical roller bearings designed to carry heavy loads, guarantees stable and long hours of trouble-free machine operation at high revolutions.

Pulleys are driven by five belts on both sides. The use of one of the most efficient drive belts on the market. A special pulley and optimised toothing enable more efficient dynamic energy transmission, greater flexibility and better heat dissipation.

The drive transmission elements are protected against damage and can be opened for servicing.

The robust, durable welded construction with a total weight of 3490 kg, assembled on high quality components from world renowned manufacturers, ensures stable operation in the most difficult terrain.

Standard equipment:

– 3-point connection, Cat III,

– 1″ 3/4 S6 input shaft

– 1000 rpm – spur gearbox

– double-sided belt drive,

– 10 V-belts (2x5pcs)

– rotor Ø 6000mm,

– interchangeable forged milling tools,

– hydraulically controlled roller

– two row front chain screen,

– outfeed points for easy lubrication

– operating speed 0-1.5 km/h

Available on demand:

– PTO shaft with unidirectional disc overload clutch x2

– movable gearbox – lower gearbox guidance system

-

Min. / zalecana moc 110-200 л.с

Szerokość robocza mulczera 2000 мм

Maksymalna średnica rozdrabniania pni 250 мм

Waga 1810 кг

Typ pracy -

Min. / zalecana moc 190-300 km

Szerokość robocza mulczera 2500 mm

Maksymalna średnica rozdrabniania pni 400 mm

Waga 3490 kg

Typ pracy Do pracy wgłębnej

-

Min. / zalecana moc 110-200 km

Szerokość robocza mulczera 2000 mm

Maksymalna średnica rozdrabniania pni 250 mm

Waga 1810 kg

Typ pracy Do pracy powierzchniowej

-

Min. / zalecana moc 110-200 km

Szerokość robocza mulczera 2000 mm

Maksymalna średnica rozdrabniania pni 250 mm

Waga 1810 kg

Typ pracy -

Min. / zalecana moc 120-200 л.с

Szerokość robocza mulczera 2250 мм

Maksymalna średnica rozdrabniania pni 250 мм

Waga 1920 кг

Typ pracy

in Poland

in Poland

in Germany

in Germany

in the Czech Republic

in the Czech Republic