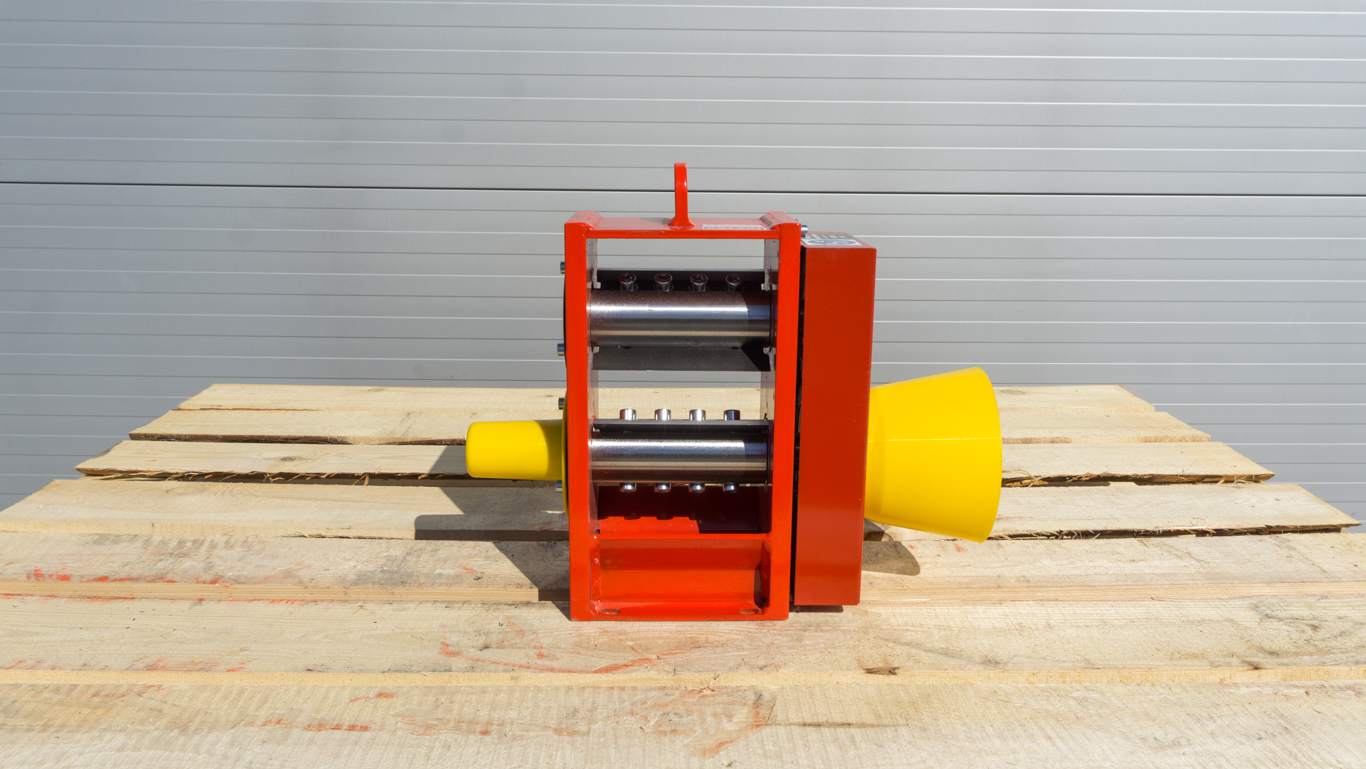

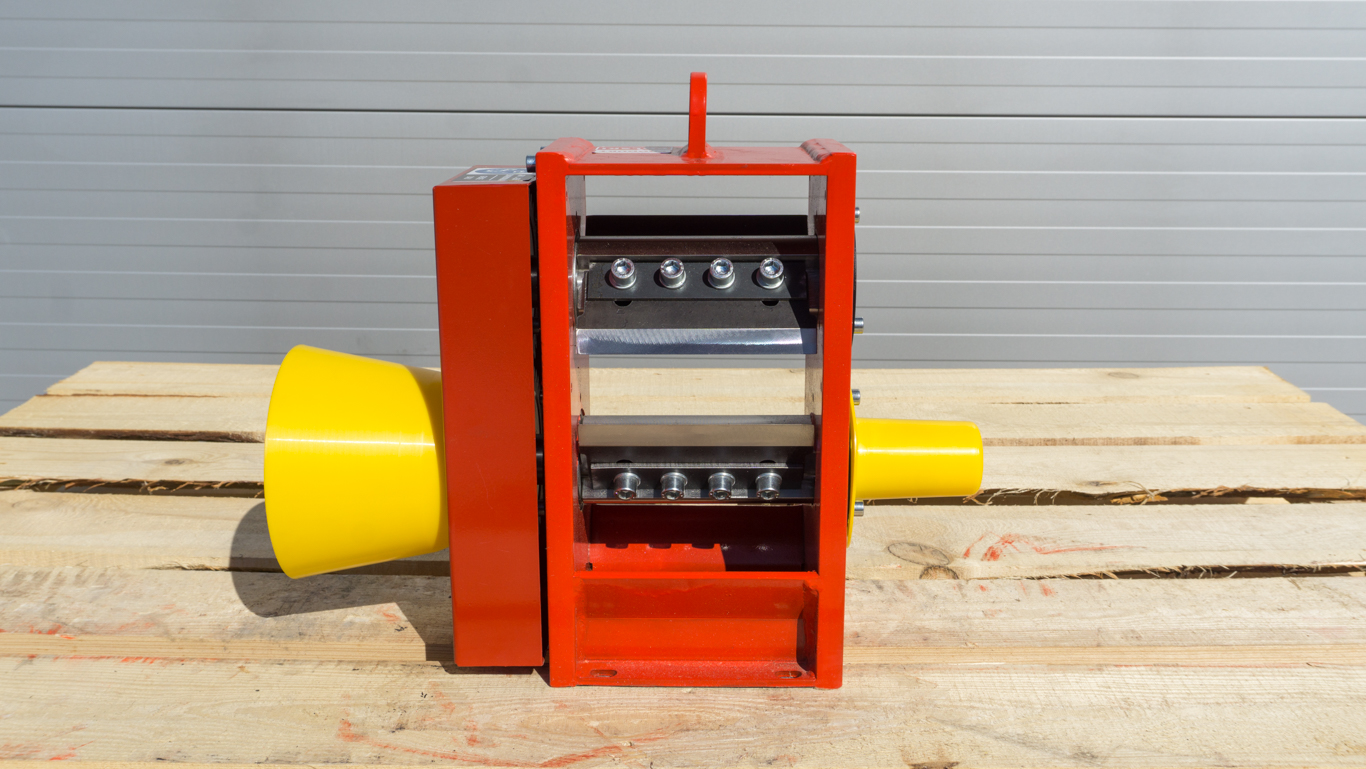

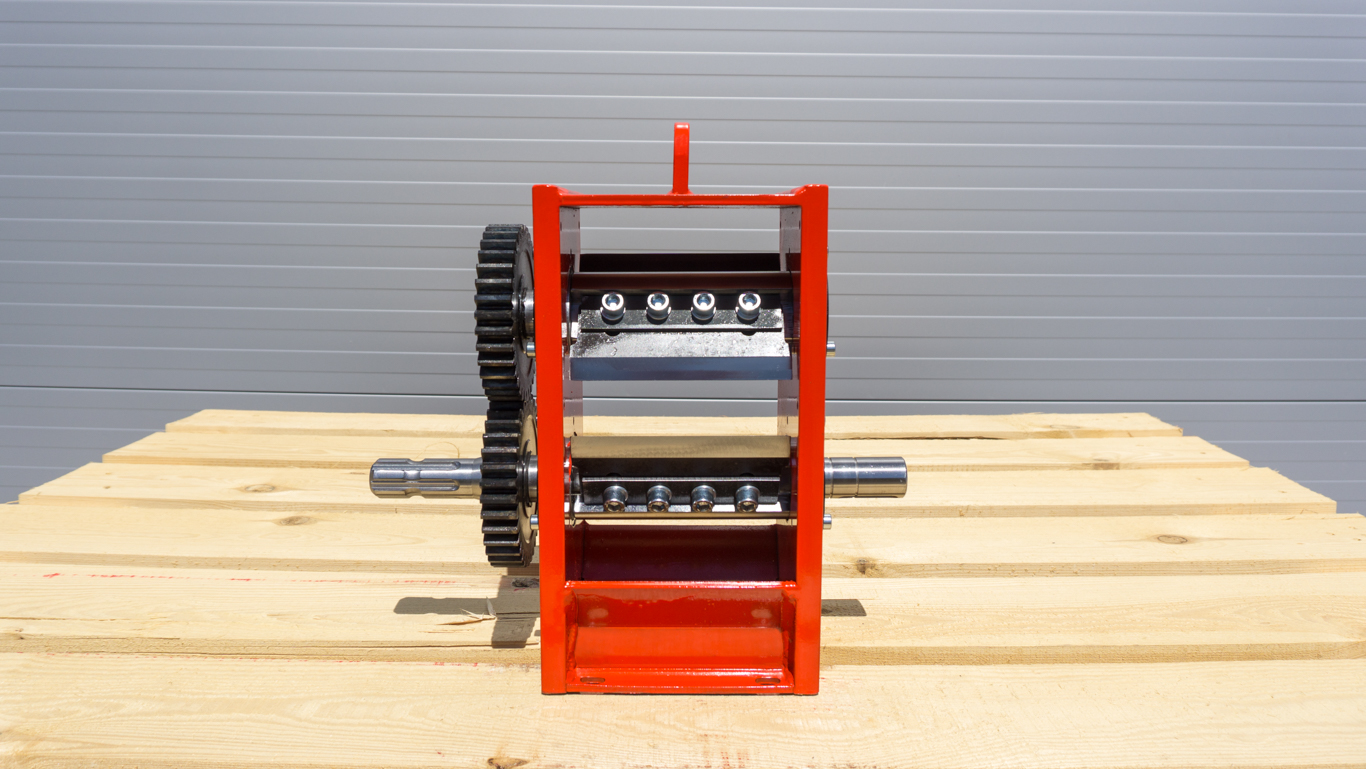

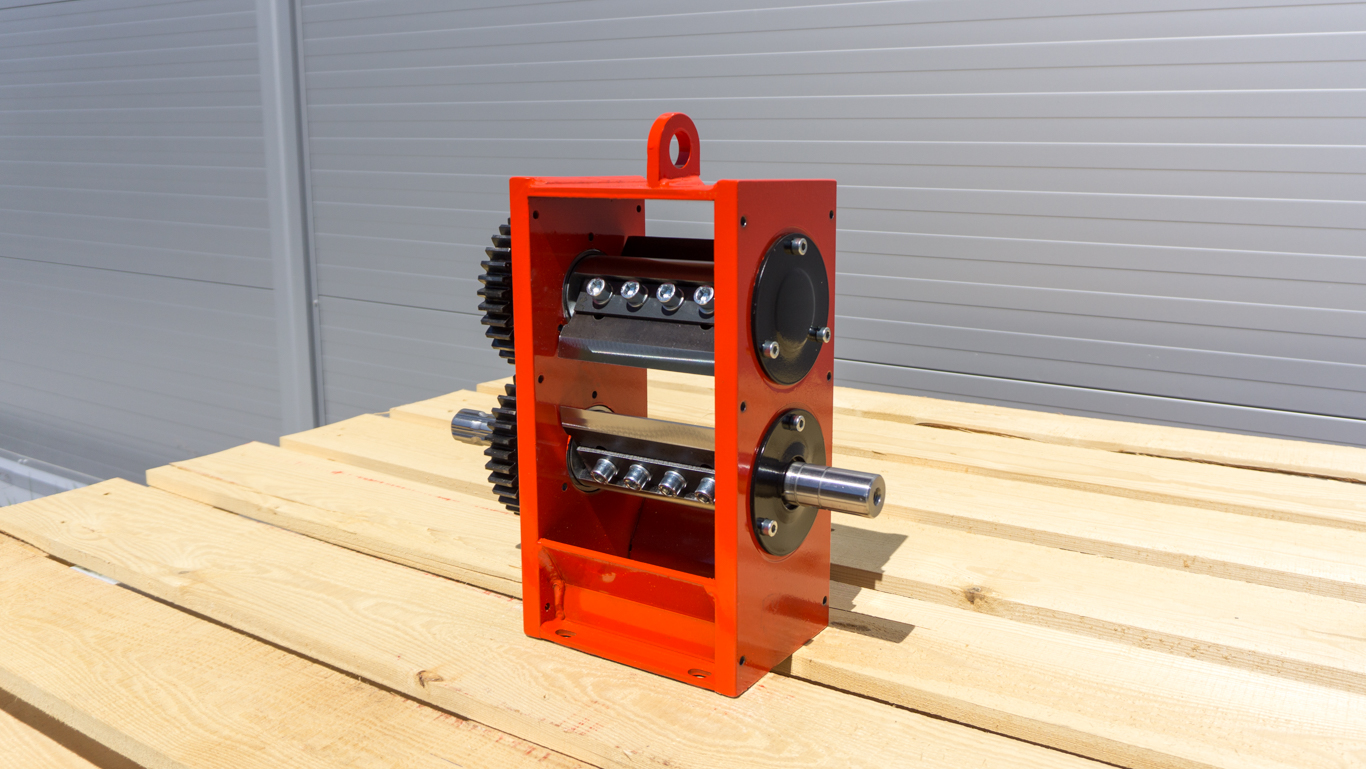

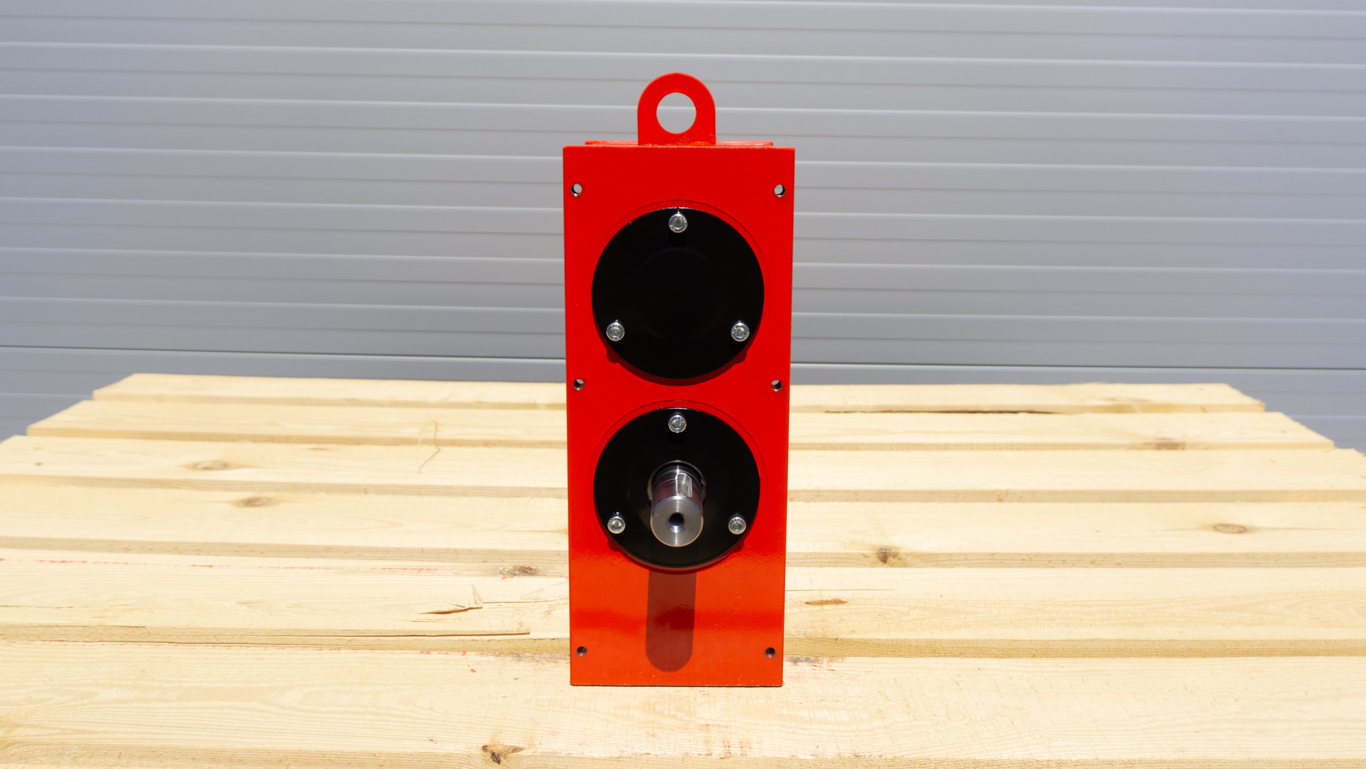

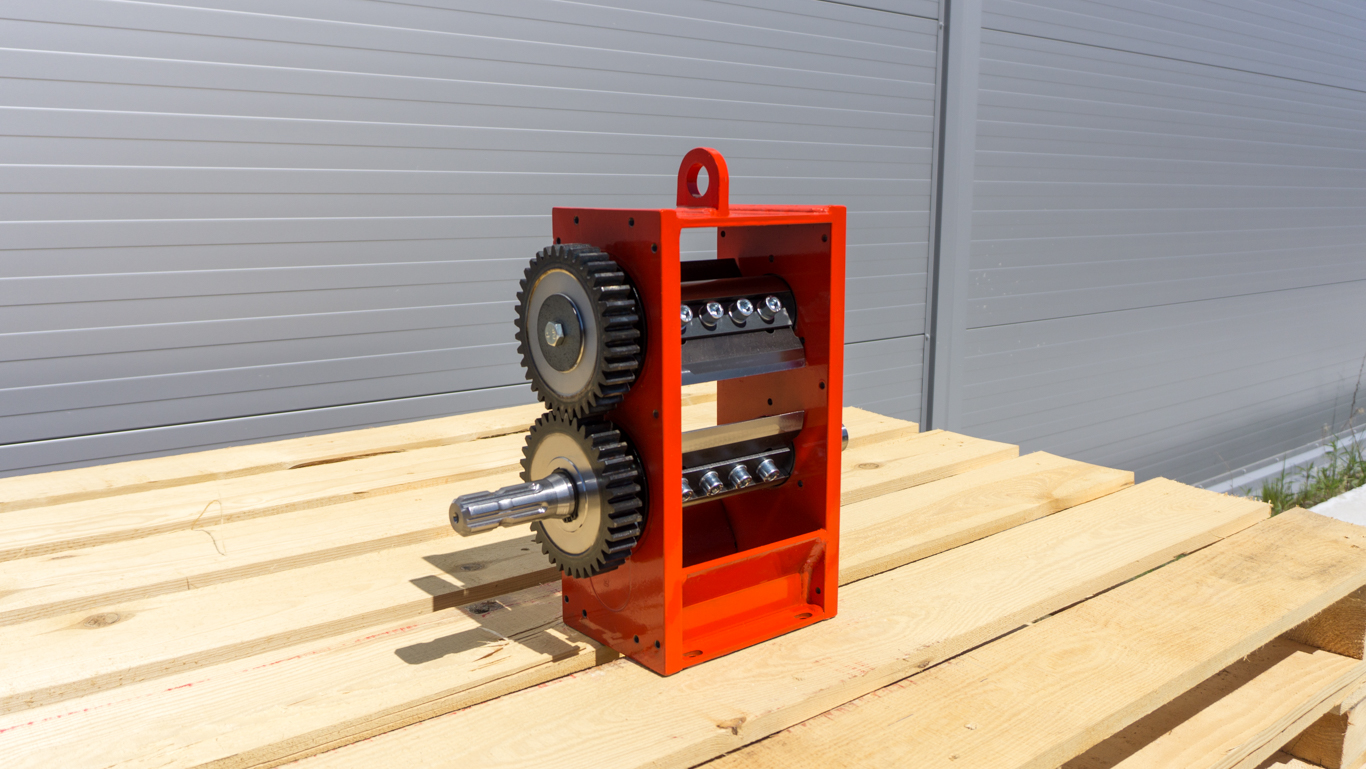

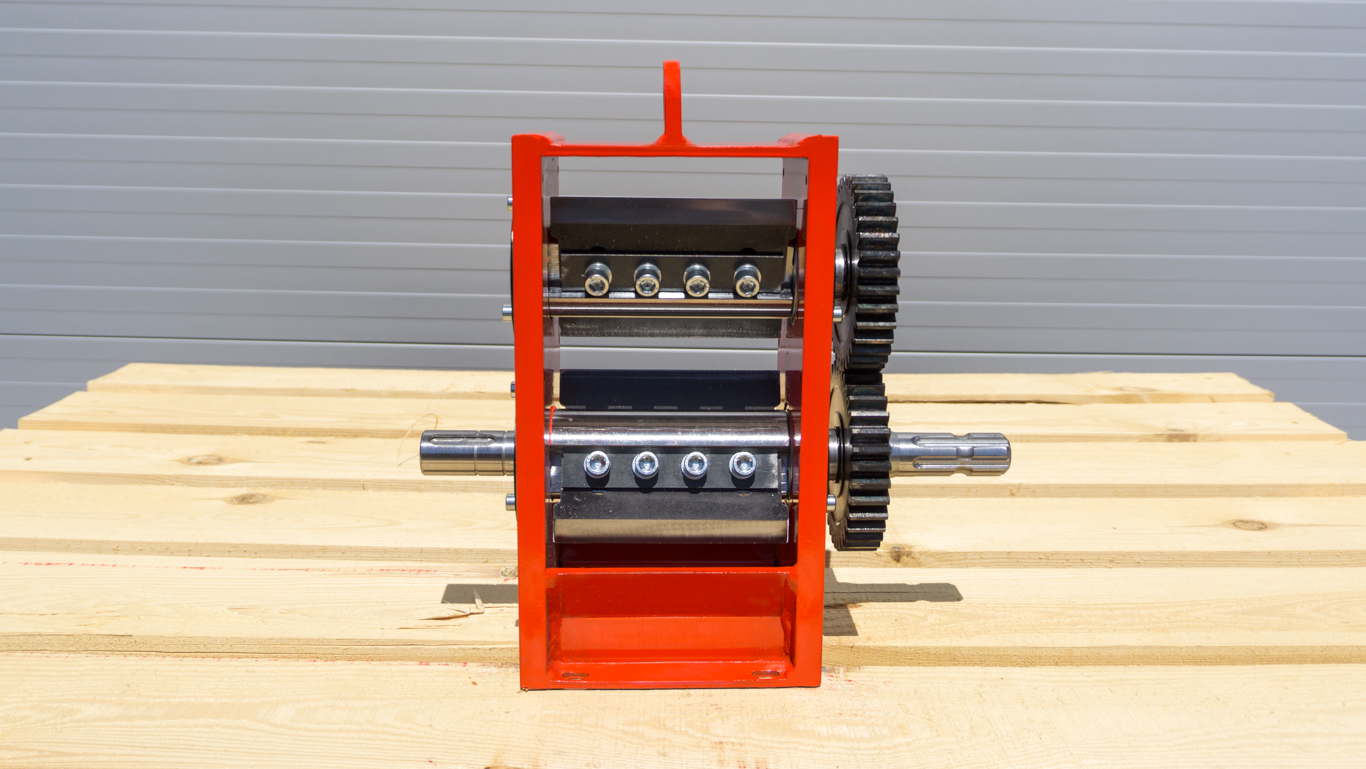

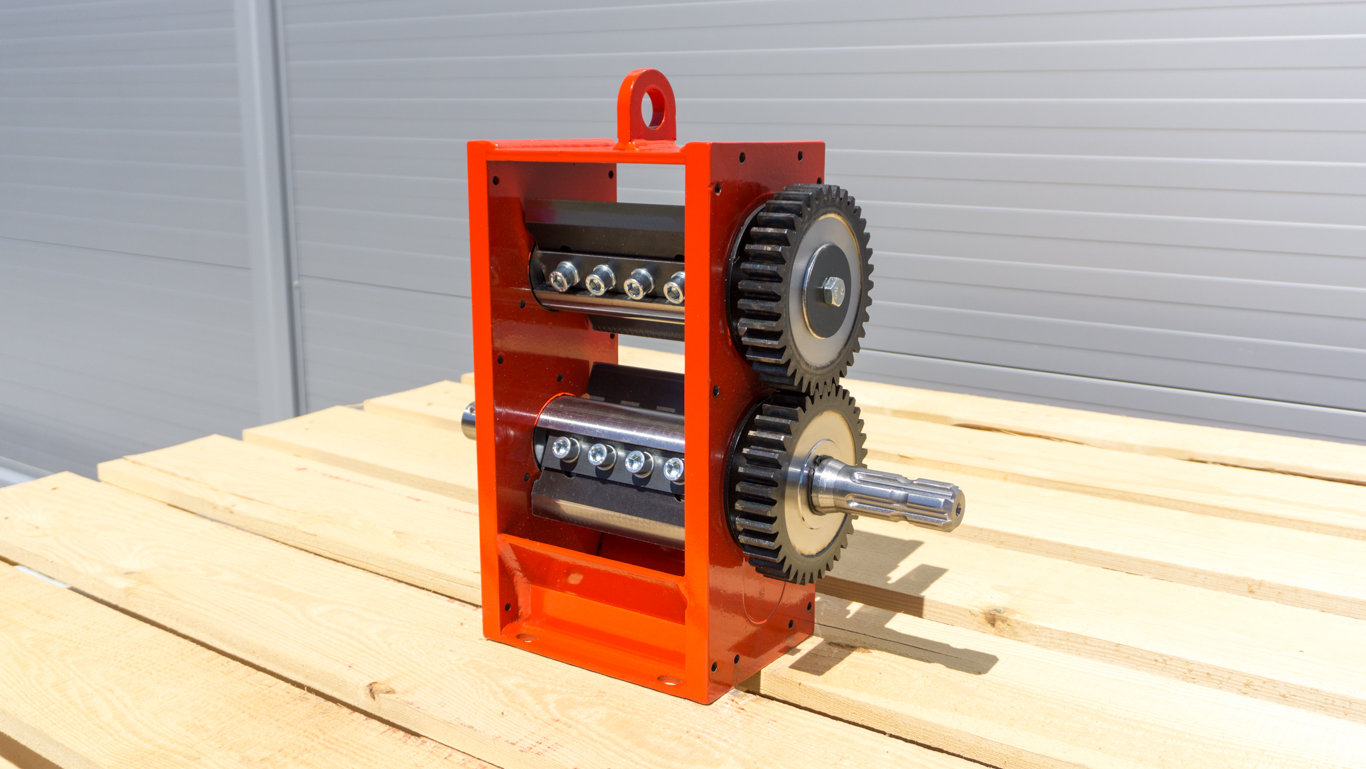

Model M-60

| Max. średnica cięcia | 5.5 cm |

|---|---|

| Długość cięcia zrębki | 4 cutters 9-15 cm |

| Min. / zalecana moc | 10 / 20 km |

| Seria produktu | standard |

M-60 cutting mechanism is designed for cutting branches with a diameter of up to 5 cm and has been designed and developed by REMET CNC TECHNOLOGY from certified 20 mm metal sheet.

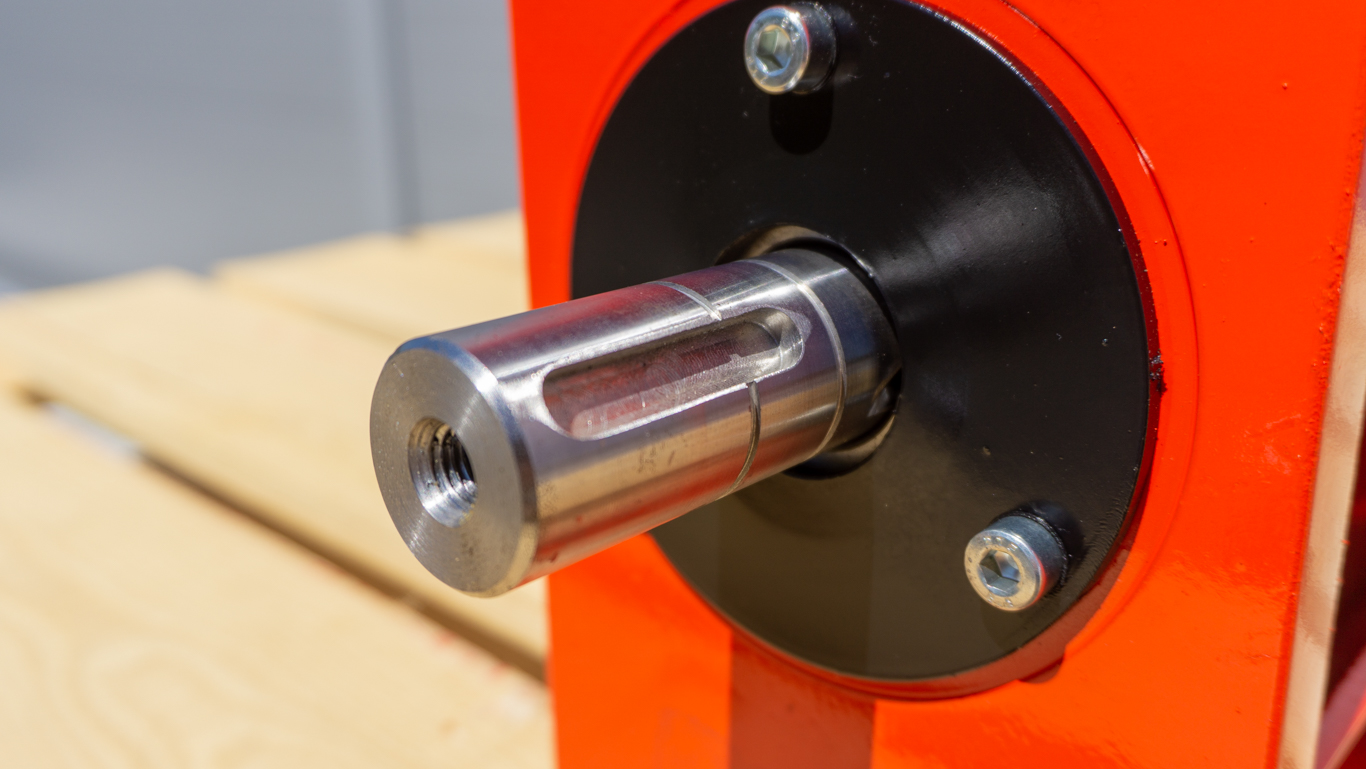

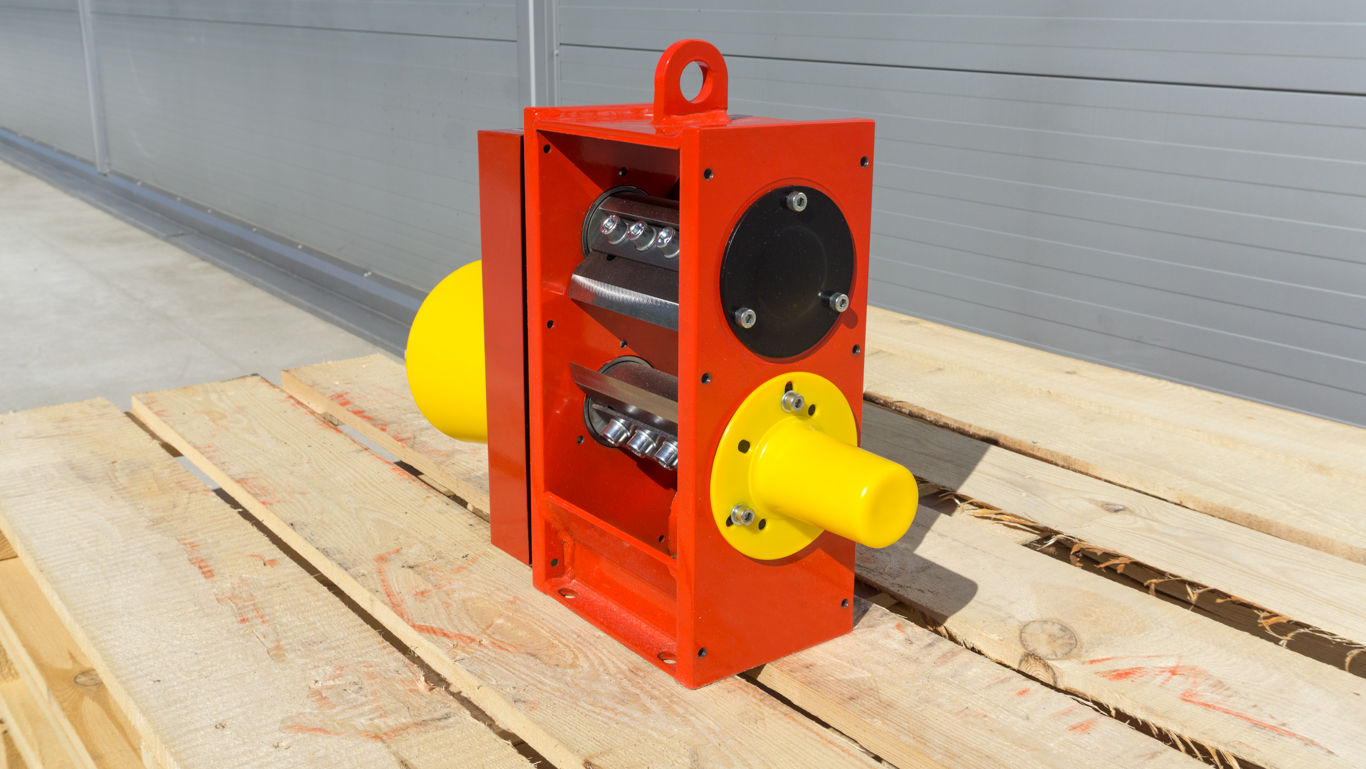

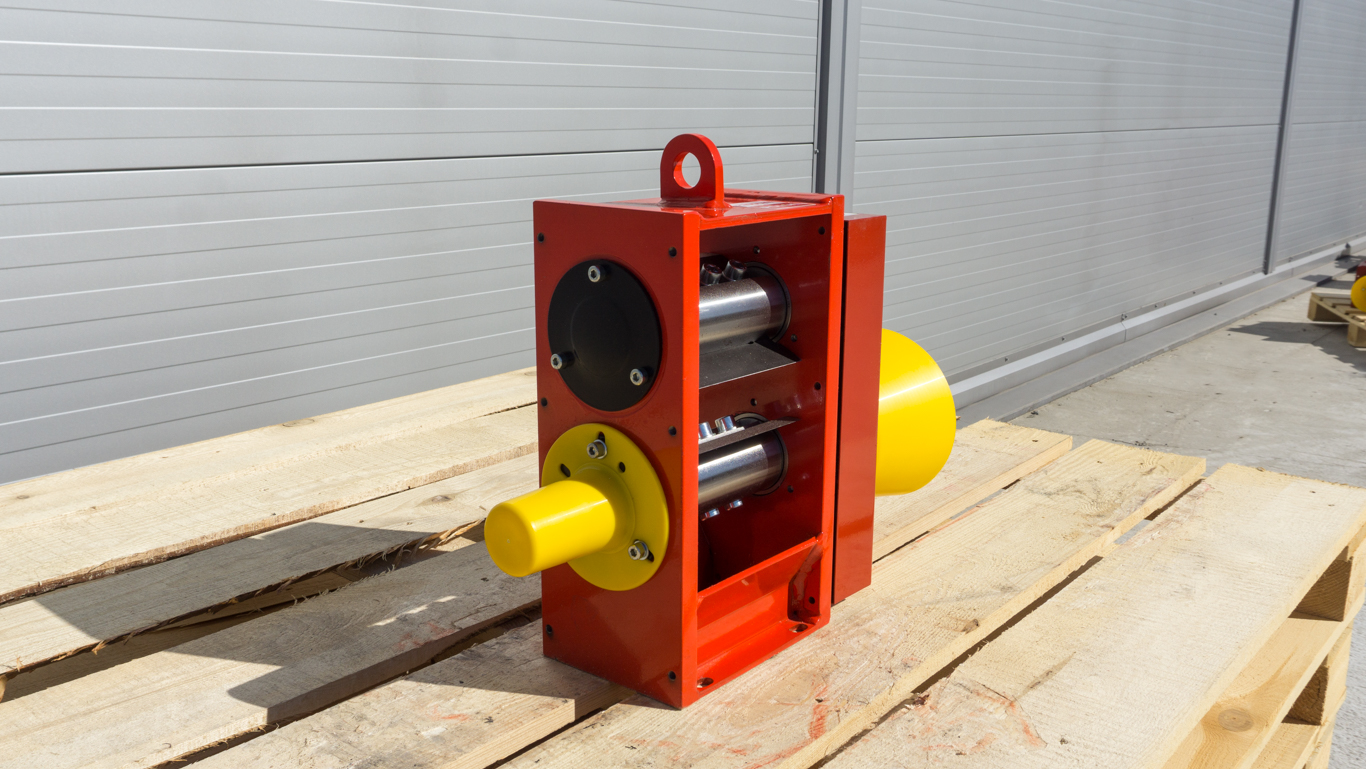

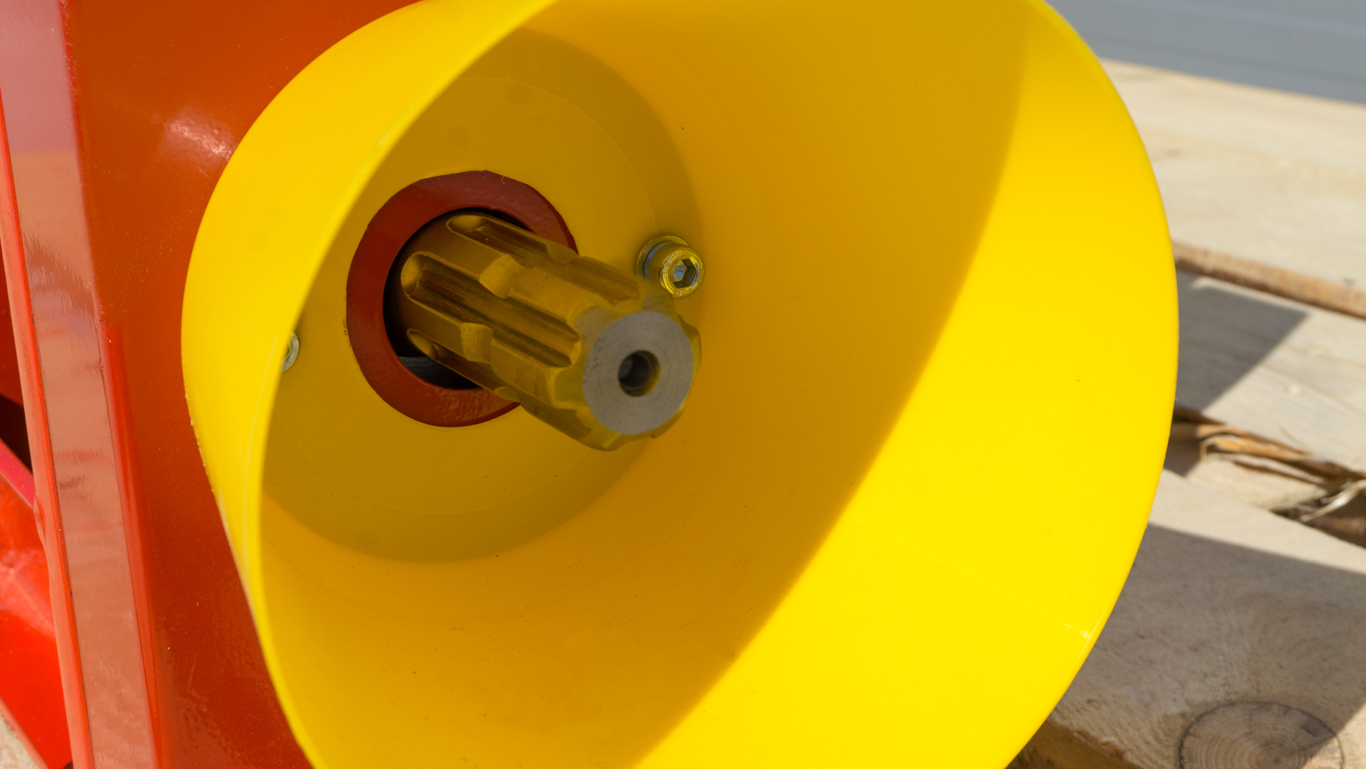

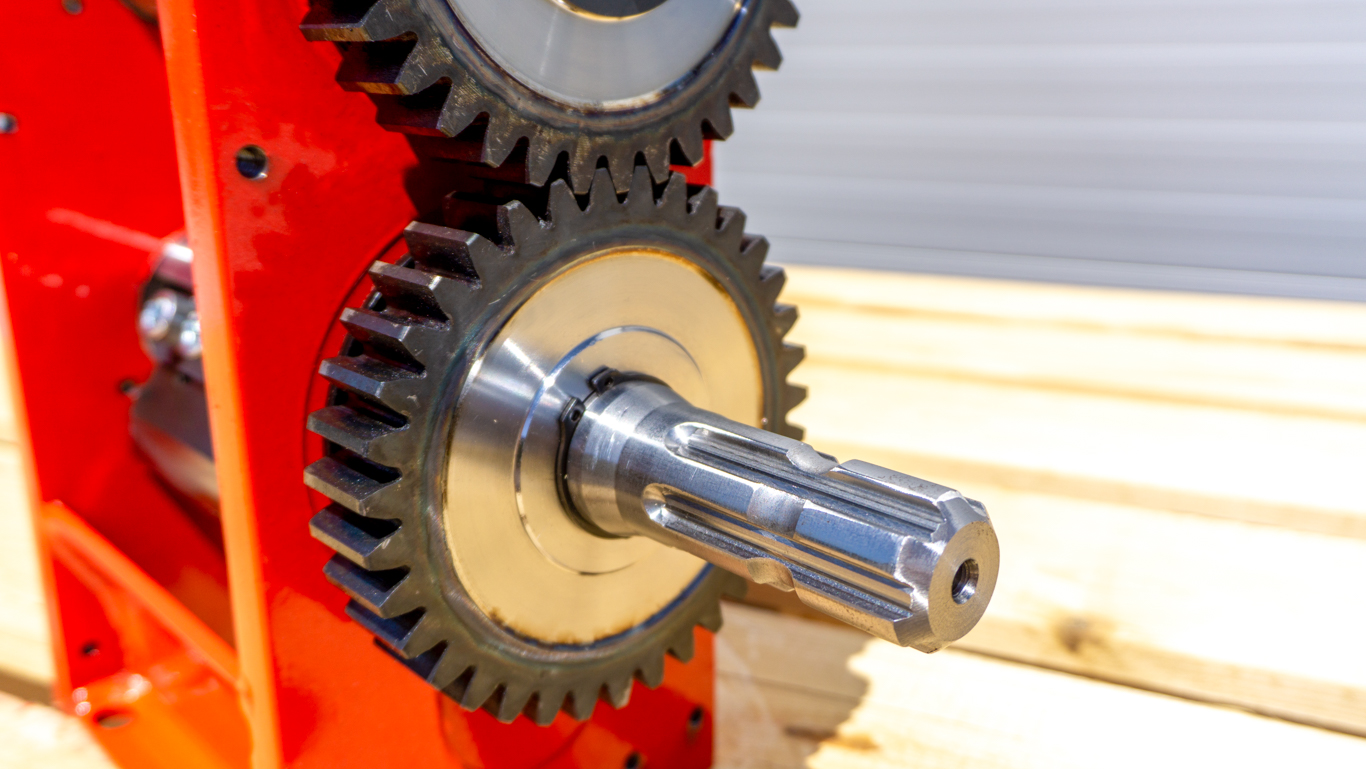

M-60 cutting mechanism is designed for cutting branches with a diameter of up to 5 cm and has been designed and developed by REMET CNC TECHNOLOGY from certified 20 mm metal sheet. Welded structure providing proper rigidity and reliance of design. Machined on the precise CNC machining centre from one assumption to provide proper quality, accuracy and axis alignment which translates into long service life of sub-assemblies and the entire device. The mechanism is fitted with an expanding and clamping sleeve which serves for the positioning of cutting blades, and also performs a function of overload protection.

Specification

- welded construction (fully dismountable)

- additional rear roller for flywheel/pulley

- adjustable clearance between cutters

- induction hardened gear wheels

- through fixing holes

- threaded holes for covers

-

standard

Max. średnica cięcia 16 cm

Długość cięcia zrębki 6 cutters 14-22 cm

8 cutters 10-15 cmMin. / zalecana moc 90 / 150 km

Seria produktu standard

-

standard

Max. średnica cięcia 11 cm

Długość cięcia zrębki 6 cutters 8-15 cm

8 cutters 5-10 cmMin. / zalecana moc 25 / 35 km

Seria produktu standard

-

standard

Max. średnica cięcia 13 cm

Długość cięcia zrębki 6 cutters 12-18 cm

8 cutters 10-15 cmMin. / zalecana moc 45 / 80 km

Seria produktu standard

-

standard

Max. średnica cięcia 4 cm

Długość cięcia zrębki 4 cutters 5-12 cm

Min. / zalecana moc 10 / 15 km

Seria produktu standard

-

standard

Max. średnica cięcia 9 cm

Długość cięcia zrębki 4 cutters 9-18 cm

6 cutters 7-14 cmMin. / zalecana moc 15 / 25 km

Seria produktu standard

in Poland

in Poland

in Germany

in Germany

in the Czech Republic

in the Czech Republic